Straton Electricals offers a wide range of custom-designed products like metering cubicles, isolation/control transformers, auxiliary transformers, tailored to meet the specific needs of our customers. Our custom products can include features such as custom winding ratios, accuracy classes, mounting options, insulation levels, and even product types. These products are designed to provide reliable, accurate, and cost-effective solutions for a wide range of applications.

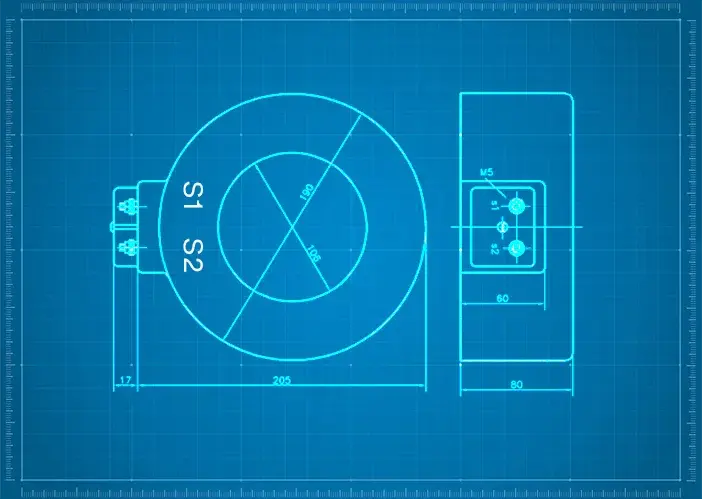

Standard current transformers also called as reference current transformers are used to compare other current transformers for their accuracy conformance. It is usually used in a laboratory or testing environment. It is designed to have a high degree of accuracy and stability to provide a reliable reference point for the comparison of other current transformers.

| Maximum primary current | 10000A |

| Possible secondary currents | 1 A; 5 A & customer specific secondaries |

| Max. secondary Insulation | 3 kV standard, 5 kV special executions |

| Max. accuracy | +/- 0.005 % |

| Max. phase angle | +/- 0.5 min |

| Measuring Range | 1 – 200 % of In |

| Burden | max. 15VA / customer specific |

| Operating Frequency | 50 – 200 Hz |

| Insulation type | Dry Insulation / Air cooled / Cast Resin |

| Weight | - |

| Dimensions | - |

| Type | Bar primary / Wound |

| Tapping | Both primary and secondary tapping can be provided according to customer specific requirement. |

Standard voltage transformers also called as reference voltage transformers are used to compare other voltage transformers for their accuracy conformance. Standard voltage transformers are used for the testing of voltage transformer accuracy and for reference to other voltage transformers in a measurement system.

| Max. primary Voltage | up to 220 kV / √3 |

| Also available in custom designs | (132 – 110 – 66) kV / √3 |

| Possible secondary voltages | 100 V, 110V, 100/√3 V, 110/√3 V and customer specific secondaries |

| Voltage Factor | 1.9 times of Un |

| Max. possible voltage accuracy | +/- 0.005 % |

| Max. possible phase angle accuracy | +/- 0.5 min |

| Measuring Range | 20 – 120 % of Un |

| Burden | internal resistance of measuring device / customer specific requirement |

| Measuring frequency | 50 & 60 Hz |

| Operating frequency | 50 – 150 Hz |

| Insulation | Oil Impregnated Paper (OIP) |

| Configuration | Single phase construction |

| Weight | - |

| Dimension | - |

| Tapping | Both primary and secondary tapping can be provided as per customer specific requirement. |

AC Test transformers are used in a variety of applications, including testing electrical equipment, such as motors, generators, and transformers etc. They are also used in industrial and commercial applications for safety purposes, such as testing and monitoring the performance of electric motors and other electrical components. Test transformers are typically rated for a specific voltage and current, and they are designed for specific applications. They are available in a variety of shapes and sizes, so it is important to select one that is suitable for the application.

| Max. Output Voltage | 130 kV |

| Input Voltage | 230V, 400 V | as per customer requirement |

| Max. Output | 5 kVA (Continuous) 10 kVA (Duty Cycle: 1 hr ON, 23 hrs OFF) |

| Tripping Current | 50 mA |

| Standard Operating Frequency | 50 or 60 Hz |

| Weight | 450 kgs (approx.) |

| Dimensions | 650 x 650 x 1400 mm (approx.) |

| Custom design acc. to customer requirement |

|

Metering cubicles are a type of electrical equipment used to provide safe and reliable power to electrical systems. They are used to measure power distribution networks, as well as providing power to other electrical systems. Metering cubicles are typically installed in industrial, commercial, and residential settings. They are used to measure the amount of electricity used. Metering cubicles are typically constructed from steel and come in various sizes and capacities. They are typically equipped with various components, such as a current transformers, voltage transformers and meters to ensure the efficient and accurate measurement of power.

| Rated Voltage | 11kV / 33kV |

| Rated Current | 1 – 2000A |

| Accuracy class | Accuracy class 0.2S / 0.2 / 0.5 / 0.5S / 1.0 |

| Burden | Burden As per customer or statutory requirement |

| Frequency | 50Hz |

| Installation | Indoor / Outdoor |

| Provisions | Provisions Energy Meter (Optional) |

An isolation transformer is a type of transformer that isolates one circuit from another. It is used in electrical engineering and electronics to convert voltages from one circuit to another without allowing any direct current to flow between the two circuits. The transformer is designed to block the flow of alternating current while allowing the transfer of power between the two circuits. This is accomplished by using two separate windings on the transformer and connecting them in such a way that the magnetic flux is cancelled out, thus preventing current from flowing between the two circuits. Isolation transformers are commonly used in applications such as medical equipment, power supplies, and industrial automation.

| solation Transformer | 1kVA – 25kVA |

| Ref. standard | IS 11171: 1985 (Reaffirmated 2006) |

| Configuration | Delta/ Star or user defined (1:1) |

| Default vector group | Dyn11 |

| Load Regulation | Better than 3% |

| Class of Insulation | H |

| Common mode noise rejection | Over 100dB up to 10kHz |

| DC Galvanic isolation | > 500M Ohms |

| Housing | Housing Sheet metal housing with input/output terminals |

Cast Resin Monoblock Epoxy Bushing is a type of bushing used in instrument transformers. It is composed of a single piece of epoxy resin and contains aluminium part. The epoxy resin provides excellent electrical and mechanical properties, making it ideal for use in instrument transformers. The resin is also highly resistant to temperature, moisture, and chemical attack, making it extremely durable. Cast Resin Monoblock Epoxy Bushings are typically used in medium and high-voltage transformers, providing a reliable and cost-effective solution for transformer secondary connection needs in terms of arresting oil leakages. This type of epoxy bushing has been proven to be very reliable in the field and has a long lifespan.

| Wires | Wires Tin plated high conductivity copper wire |

| Wire insulation | PTFE |

| No. of terminals connections Up to 17 | Up to 17 |

| Insulation class | H |

| Insulation level | 3kV for 1 min. |

Standard voltage transformers also called as reference voltage transformers are used to compare other voltage transformers for their accuracy conformance. Standard voltage transformers are used for the testing of voltage transformer accuracy and for reference to other voltage transformers in a measurement system.

| Max. primary Voltage | up to 40 kV / √3 |

| Possible secondary voltages | 100 V, 110V, 100/√3 V, 110/√3 V and customer specific secondaries |

| Voltage Factor | 1.9 times of Un |

| Max. possible voltage accuracy | +/- 0.01 % |

| Max. possible phase angle accuracy | +/- 1 min |

| Measuring Range | 60 – 120 % of Un |

| Burden | internal resistance of measuring device / customer specific requirement |

| Measuring frequency | 50 & 60 Hz |

| Operating frequency | 50 – 150 Hz |

| Insulation | Cast Resin |

| Configuration | Single phase construction |

| Weight | 50 kg |

| Dimension | 225 x 270 x 290 mm |

| Tapping | Secondary tapping can be provided as per customer specific requirement |

Standard voltage transformers also called as reference voltage transformers are used to compare other voltage transformers for their accuracy conformance. Standard voltage transformers are used for the testing of voltage transformer accuracy and for reference to other voltage transformers in a measurement system.

| Max. Primary Voltage | up to 60 kV |

| Possible secondary voltages | 100 V, 110V, 100/√3 V, 110/√3 V, 100/3 V, 110/3 V, 230 V and customer specific secondaries |

| Voltage Factor | 1.9 times of Un |

| Max. possible voltage accuracy | +/- 0.01 % |

| Max. possible phase angle accuracy | +/- 1 min |

| Measuring Range | 60 – 120 % of Un |

| Burden | internal resistance of measuring device / customer specific requirement |

| Operating frequency | 50 – 150 Hz |

| Insulation | Cast Resin |

| Configuration | Two phase construction |

| Weight | 80 kg |

| Dimension | 450 x 300 x 850 mm |

| Tapping | secondary tapping can be provided as per customer specific requirement |