Current Transformers (CTs) function as foundational elements of contemporary electrical grids, ensuring accurate current measurement and supplying reliable, isolated signals to protection systems. While their two major designs, bar-type and wound-type embody two distinct construction styles and serve fundamentally different operating roles. The wound type of current transformer employs a primary winding wrapped around the magnetic core, offering flexibility in turns ratio and burden capacity for medium-voltage applications. In contrast, the bar type current transformer utilizes the busbar itself as a single-turn primary conductor passing through the core window, delivering compact construction and superior accuracy at higher current ratings.

Understanding current transformer selection criteria including primary current magnitude, burden requirements, accuracy class, and installation constraints determines optimal CT design selection for substations, switchgear, and industrial automation systems. This technical comparison examines construction principles, electromagnetic performance characteristics, and application-specific advantages to guide engineering decisions for reliable current measurement infrastructure.

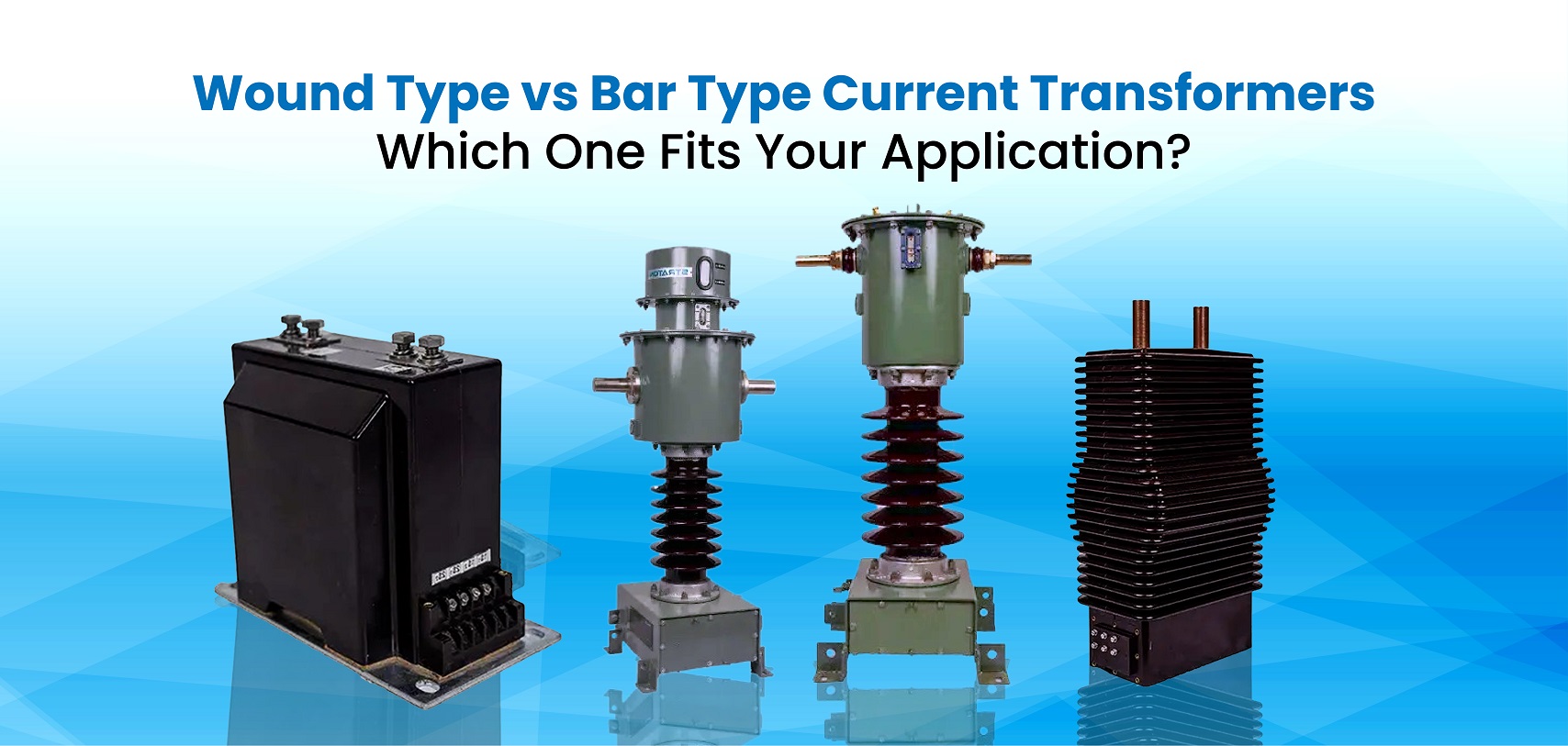

A Technical Comparison of Wound Type and Bar Type CTs

The construction and performance characteristics of wound type and bar type current transformers differ across key parameters that directly influence selection for substation and switchgear applications. The table below highlights how primary configuration, accuracy behavior, and mechanical performance vary, so designers can map each CT construction to the intended metering or protection application.

| Parameter | Wound Primary CT | Bar Primary CT |

| Primary construction | Multi-turn insulated copper winding wound concentrically on the magnetic core. Number of turns fixed during manufacture. | Solid busbar or conductor forms a single-turn primary passing directly through the CT core. |

| Typical primary current range | Low to medium currents, typically 1 A to 300 A (occasionally up to 800 A for special designs). | Medium to very high currents, typically 400 A to 5000 A and above. |

| Short-time current (STC / Ith) | Lower short-time thermal withstand due to smaller conductor cross-section and higher winding resistance. | High STC capability as the primary conductor is a solid busbar designed for high fault currents. |

| Accuracy class | Common classes 0.5, 1.0, and 5P/10P for metering and protection in low-current circuits. | Superior accuracy classes 0.2S and 0.5S due to minimal primary losses and strong magnetic coupling. |

| Primary power loss | Higher I²R losses in the primary winding increase thermal rise and burden. | Negligible primary losses due to a single-turn, low-resistance busbar. |

| Thermal performance | Limited by copper winding size and insulation class. | Excellent thermal performance; heat dissipation handled mainly by the busbar. |

| Ratio flexibility | High flexibility by selecting multiple primary turns during manufacture. | Single-turn primary fixes ratio; secondary turns set for required transformation. |

Wound-type current transformer construction employs multi-turn primary windings wound concentrically around a laminated silicon-steel core, with secondary windings providing standardized 1 A or 5 A rated secondary current in accordance with IEC 61869-2 and IEEE C57.13.

This design enables precise turns ratio selection and supports IEC accuracy classes 0.2, 0.5, and 1.0, as well as IEEE metering and protection classes, making wound-type CTs suitable for both revenue metering and protection applications.

Wound-type CTs are designed to meet short-time current withstand requirements and thermal rating factor (RF) specified by IEC and IEEE standards. Their applications in feeder protection, energy metering panels, and motor control centers align with standard-compliant medium-current measurement requirements (typically 5 A to 800 A) defined in distribution switchgear installations.

Bar type current transformers utilize a single-turn primary conductor, typically a rigid insulated bar, integrated within a laminated magnetic core. This configuration provides high mechanical strength and short-circuit current withstand capability compliant with IEC 61869-2 and IEEE C57.13 requirements.

The secondary winding produces standardized 1 A or 5 A secondary output, supporting IEC protection and metering accuracy classes and corresponding IEEE relay accuracy classifications.

Bar-type CTs are particularly suited for high-current and high-fault-level applications, where compliance with rated short-time thermal current (Ith) and dynamic current (Idyn) requirements is critical. Their widespread use in busbar systems, power distribution equipment, and system protection instrumentation reflects their conformity with IEC and IEEE installation and performance criteria.

In the world of power system measurement, the choice between a wound type CT and a bar type depends on system current rating, space availability, accuracy requirements (burden specifications, VA ratings) and environmental conditions (temperature coefficients, humidity resistance). A wound type current transformer (wound type CT) offers flexibility for low-current applications requiring precise measurement, while a bar type current transformer (bar type CT) is ideal for compact installations and high-current systems. Both wound type CT and instrument transformers technologies integral to substation current transformer applications demand meticulous evaluation of core material saturation limits, knee-point voltage, and composite error margins for optimal power system protection coordination.

A wound-type current transformer is an instrument transformer with separate primary and secondary windings wound around a laminated magnetic core. Its primary winding consists of multiple turns of high flexible conductor size connected in series with the circuit. This construction allows for high accuracy and precise current transformation for metering and protection applications in electrical panels and substations.

A bar-type current transformer is an instrument transformer commonly used in electrical substations. It features a single-turn primary conductor, usually a solid insulated bar, surrounded by secondary windings on a laminated core. This design allows high current handling, robust operation, and reliable functioning under harsh electrical and mechanical stress.

Wound-type CTs offer superior accuracy, flexibility in ratio selection, and a compact design well suited for low primary current measurement. They provide precise current transformation and excellent excitation characteristics, making them ideal for sensitive protection and metering in electrical panels and low to medium voltage applications.

Bar-type CTs provide high current handling capacity, strong mechanical structure, low maintenance, and excellent insulation reliability. They are effective in heavy-duty environments like substations and industrial power distribution, offering robustness required for high fault currents and stable operation in power transformers and substation equipment.

Use wound-type CTs for low to medium current measurement in compact electrical panels requiring high accuracy. Bar-type CTs suit high current, industrial applications, and substations with busbar installations needing mechanical strength and high fault current tolerance. Consider CT selection guides based on application, installation location, and current range.

Current transformers include wound type CTs with multi-turn primaries, bar type CTs with single bar primary conductors, toroidal CTs with ring-shaped cores, and core balance CTs used for protection. These instrument transformer classifications vary by construction and application in power systems and substations.