Current Transformers (CTs) are defined by their primary conductor: wound-type for low currents, bar-type for high currents, and toroidal for bus-bar mounting. Core construction uses grain-oriented silicon steel or Nano crystalline alloys for precision. Inductive Voltage Transformers (IVTs) employ a single-stage (for medium and high voltage) or cascaded two-stage (for extra high voltage) design to manage insulation stress. Both devices are engineered to specific CT and IVT specifications, like accuracy class and thermal rating. As specialized Current Transformer manufacturers, Straton Electricals focuses on the core geometry and winding techniques that define performance, providing units that integrate seamlessly into protection and metering schemes.

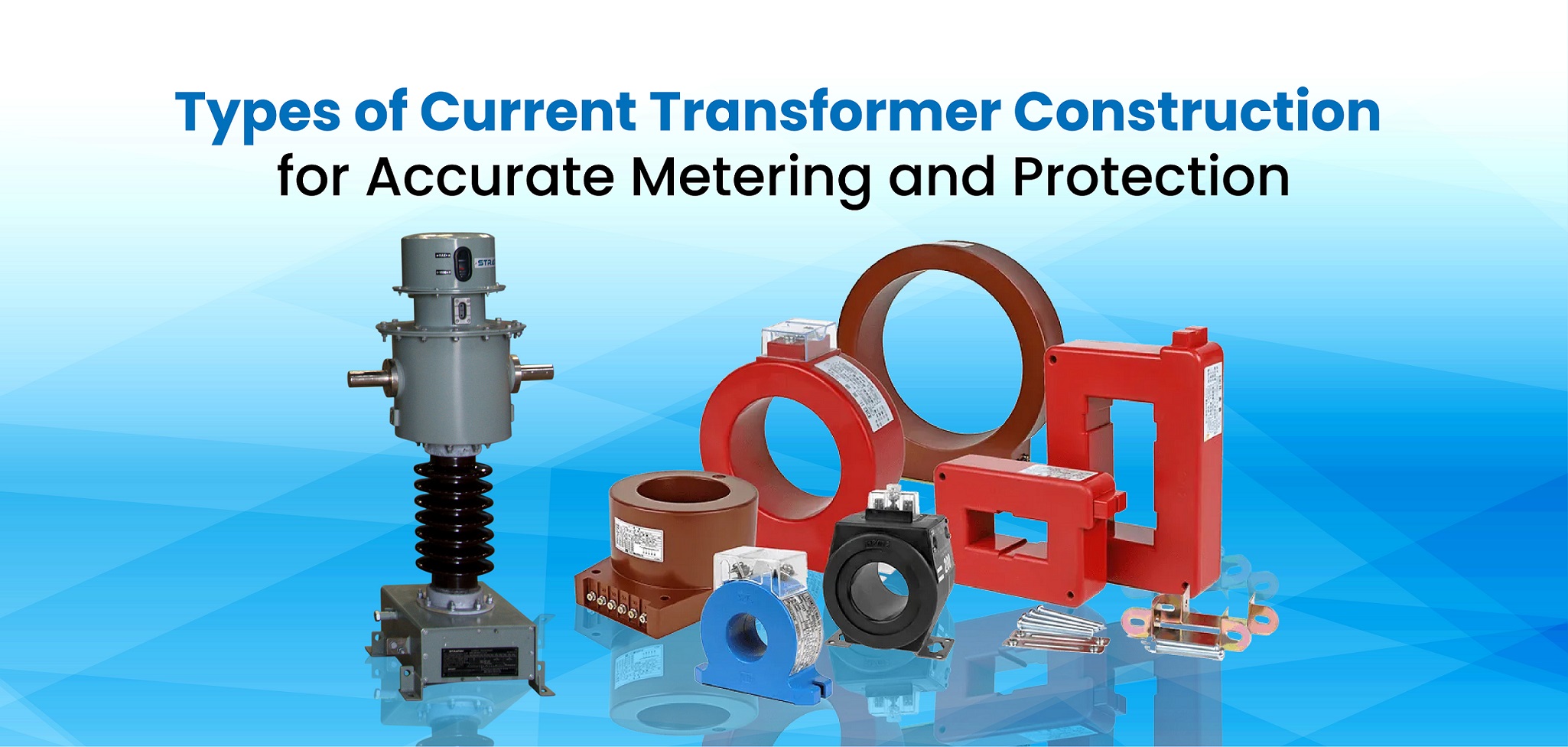

Straton Electricals Pvt. Ltd. design and manufacture a wide range of instrument transformers for electrical substation applications, covering voltage classes from 3.3 kV to 245 kV. The construction type of a CT is selected based on system voltage, current rating, installation environment, and accuracy requirements.

Window-Type Current Transformers are designed with a ring or toroidal core configuration, allowing primary conductors such as bus bars or power cables to pass directly through the CT window. This construction is well suited for high-current applications up to 10,000 A, with cast-resin insulation ensuring uniform dielectric strength and reliable insulation performance.

Wound-Type Current Transformers utilize a primary winding wound over the magnetic core and insulated using oil-impregnated paper insulation with fine-graded bushings. These CTs are commonly used in medium-voltage systems, where they convert high primary currents up to 2,000 A into standardized secondary outputs of 1 A or 5 A for metering and protection relays.

Bar-Type Current Transformers incorporate a fixed primary conductor passing through the core, providing excellent ratio accuracy and stability, particularly for energy metering and revenue measurement applications.

Modern cast resin current transformers, manufactured in accordance with DIN 42600 standards, are widely used in indoor substations due to their maintenance-free operation, compact design, and enhanced safety characteristics.

For outdoor electrical substations, CTs constructed using cycloaliphatic epoxy resin offer superior resistance to UV radiation, thermal stress, mechanical shock, and environmental pollution, ensuring long service life under harsh operating conditions.

In practice, nearly 60% of current transformer production consists of custom-designed CT solutions, developed to meet specific customer requirements such as non-standard current ratios, special accuracy classes, space constraints, or unique mounting arrangements.

Inductive Voltage Transformers (IVTs) are constructed using a core-and-coil assembly housed within a suitable insulation medium, designed to step down high system voltages to standardized secondary voltages for metering, protection, and control purposes.

Dry Type (Cast Resin) Inductive Voltage Transformers feature cores and windings fully encapsulated in solid epoxy resin. These IVTs are commonly used in medium-voltage indoor applications, offering high safety, low maintenance, and excellent resistance to moisture and contamination.

For higher voltage applications, oil-immersed inductive voltage transformers are widely adopted. These designs employ oil and paper insulation systems, providing improved cooling performance and higher dielectric strength, making them suitable for outdoor and high-voltage substations.

In specialized or space-constrained environments, gas-insulated IVTs using SF₆ gas may be employed. This construction offers compact dimensions and high dielectric performance, particularly in gas-insulated substations (GIS).

It is important to note that all the above designs operate on the inductive principle. For extra-high and ultra-high voltage systems, an alternative solution is the Capacitive Voltage Transformer (CVT), which utilizes a capacitive voltage divider and a different operating principle compared to IVTs.

Current Transformers (CTs) and Inductive Voltage Transformers (IVTs) are both essential instrument transformers, but their construction differs significantly due to the nature of the electrical quantities they measure. Instrument transformer manufacturers in India like Straton Electricals design CTs and IVTs using distinct construction methodologies to meet specific measurement, protection, and insulation requirements in power systems.

From a performance perspective, burden and impedance characteristics differ by design. CTs are engineered to carry high primary currents while operating with low-impedance secondary circuits, ensuring accurate current reproduction under varying load conditions. IVTs, on the other hand, are designed to deliver a stable secondary voltage and therefore operate with higher impedance characteristics, maintaining voltage accuracy across a defined burden range.

Finally, application-based construction requirements influence both transformer types. Protection-class CTs are designed with higher accuracy limits, extended knee-point voltages, and short-time thermal and dynamic current withstand capabilities. Metering-class IVTs prioritize voltage accuracy at rated conditions, with construction optimized for precision rather than high thermal or fault current endurance.

The application of current transformers (CTs) and inductive voltage transformers (IVTs) is closely linked to their construction type, accuracy class, and insulation system. Different construction methodologies enable instrument transformers to meet specific requirements for protection, metering, monitoring, and control across electrical power transmission and distribution networks.

Regular electrical power equipment maintenance through scheduled instrument transformer inspection minimises downtime and prevents accuracy degradation. Let’s explore this in detail below.

Annual Inspection Protocols: Industry standards recommend transformers be inspected and tested at least once annually, with oil testing every three to five years. Current transformer maintenance includes visual examination of bushings for cracks, discoloration, or tracking, verification of terminal tightness, and oil level monitoring in liquid-filled units to detect leakage indicating seal degradation.

Transformer Insulation Testing: Megohmmeter tests assess insulation integrity, while polarity checks and ratio measurements verify accuracy compliance. Inductive voltage transformer maintenance uses dissolved gas analysis to detect moisture and contaminants in oil-filled units, with dielectric frequency response testing providing superior moisture assessment compared to traditional 50/60 Hz power factor tests.

CT and IVT Operational Safety: Burden measurements must be compared against transformer ratings to prevent overload conditions while thermal imaging identifies hotspots at connections. Critical: CT secondary circuits must never be open-circuited during operation. This generates dangerous voltages and core saturation risks per instrument transformer safety standards.

The primary purpose of a Current Transformer (CT) is current measurement. As an instrument transformer, it steps down current safely for monitoring and protection in electrical power system applications.

The three most common Current Transformer (CT) construction types are

Typical IVT applications include voltage measurement, potential transformer are used in power grid systems, electrical substations, switchgear panels, and metering equipment, supporting power system protection and compliance with Straton Electricals solutions.

Regular inspection, insulation testing, secondary terminal checks, oil level monitoring (where applicable), and calibration testing ensure reliability.

CVT vs IVT difference lies in the voltage measurement principle: Capacitive Voltage Transformer (CVT) uses capacitive division, while Inductive Voltage Transformer (IVT) relies on magnetic induction for power transmission metering in substations.

Types of transformer construction include Core-Type Transformer, Shell-Type Transformer, Dry-Type Transformer, and Oil-Immersed Transformer. These electrical transformer types cover Power Transformers, Distribution Transformers, and Instrument Transformer designs, ensuring reliable performance across diverse industrial and utility applications.

An Inductive Voltage Transformer (IVT) is a Potential Transformer (PT) that steps down high voltages to safe, measurable levels. This instrument transformer enables accurate metering and protection in electrical power systems.

Current Transformers (CTs) and Voltage Transformers (VTs) are instrument transformer types used in electrical substations. CT and VT difference lies in measuring current or voltage, ensuring accurate metering and power system protection across diverse applications.